SHAW - OPTIMUM TU-3008G Bench Lathe 300 x 700mm Turning Capacity - 38mm Spindle Bore

Confirm if additional costs apply

SHAW - OPTIMUM TU-3008G Bench Lathe 300 x 700mm Turning Capacity - 38mm Spindle Bore : $3,690 AUD ($4,059 Inc. GST)

OPTIMUM TU-3008G Opti-Turn Bench Lathe

300 x 700mm Turning Capacity

38mm Spindle Bore Geared Head-Stock & Enclosed Gearbox

This new TU-3008G model geared head lathe of very modern design has many convenient facilities ideal for the enthusiastic model engineer for small component manufacturer. A very rigid 180mm cast iron bed width, induction hardened and ground slideways gives a high level of precision turning. The lathe capacity is 700mm between the centres and 300mm swing over the bed and with a generous 38mm spindle bore allowing larger stock to be placed through the headstock. The workhorse that drives this lathe has an upgraded powerful 2hp (1.5kW) motor providing smooth running.

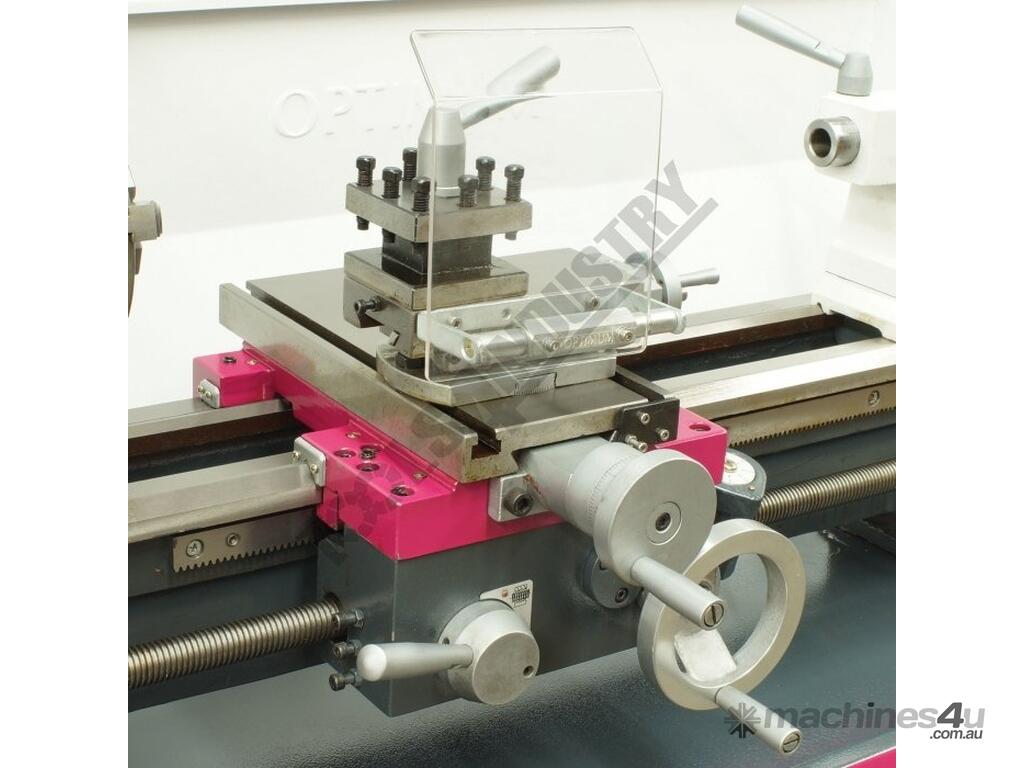

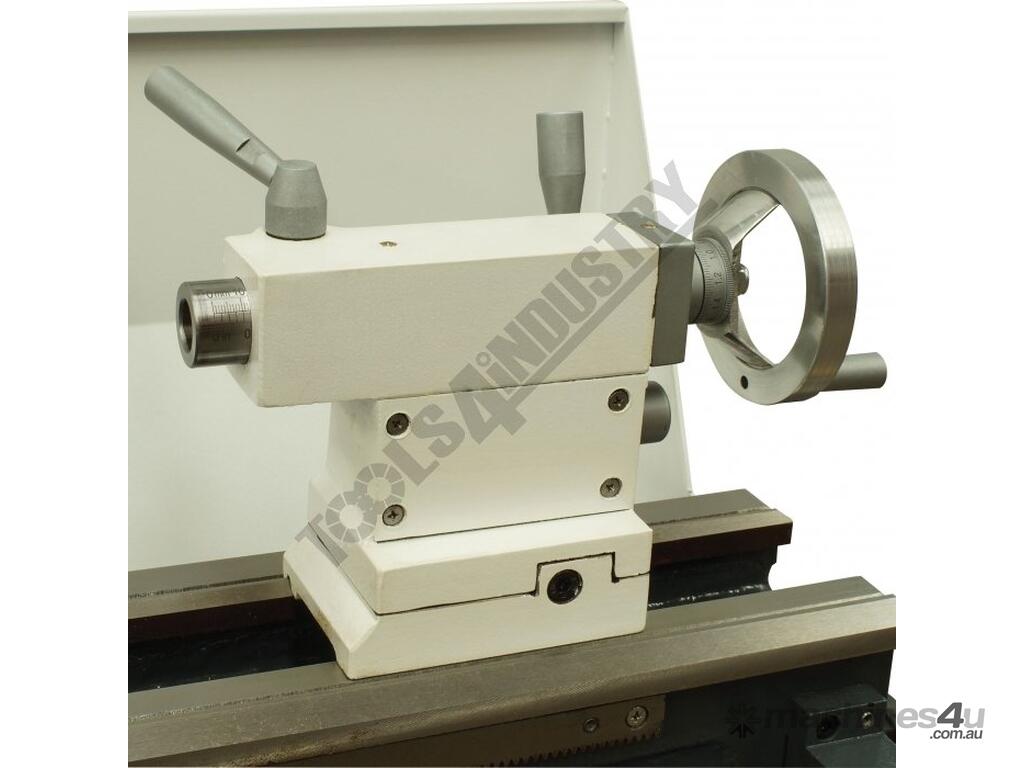

Other very useful features included are cross and longitudinal power feeds that's not normally found of small conventional lathes, quick lock tailstock and both metric and imperial thread cutting, ranging from 8-56 tpi or 0.2-3.5mm pitch. Also included are a 4-way indexing tool post with 16mm tool shank capacity, fine adjustment on the tailstock for taper turning and the rear splash guard. A 160mm 3-jaw chuck with reverse jaws is also supplied. There are many additional options available including a milling head (BF-16AV) or (BF-20AV) to turn this machine into a very capable all round machining centre.

Features:

Geared headstock for quick change of 12 spindle speeds 125-2400rpm

Ribbed prism bed made of grey cast iron

Inductively hardened and ground bed guideways

Automatic cross & longitudinal power feeds

Spindle nose accuracy 0.009mm

3 Jaw chuck running accuracy 0.04mm

D1-4 camlock spindle for quick chuck changes

Forward & reverse spindle direction switch

Oils sight glass on head-stock & gearbox

Change gears for metric and imperial thread cutting

Enclosed feed and threading gearbox

Belt cover with tamper proof safety micro switch

Heavy duty rotating safety chuck guard with micro switch

Sliding tool post safety guard

Cross slide & bed length are designed to fit Optimum DRO scales

Includes:

- Change gears for metric & Imperial thread cutting

- Chuck guard

- Toolpost guard

- 2 dead centres

- 3-jaw chuck with reversible jaws

- Swarf drip tray

- Rear splash guard

Specifications:

MODEL: TU-3008G

Swing Over Bed (mm): 300

Distance Between Centres (mm): 700

Spindle Bore (mm): 38

Swing In Gap (mm): ~

Swing Over Cross-slide (mm): 190

Digital Readout System Fitted: Optional

Quick Change Toolpost Fitted: Optional

Leadscrew Covers Fitted: ~

Taper Turning Attachment: ~

Coolant System: ~

Tool Height To Suit (mm): 16

Centre Height (mm): 150

Spindle Nose Size or Type: D1-4

Bed Width (mm): 180

Headstock Spindle Taper (MT): 5

Tailstock Taper (MT): 3

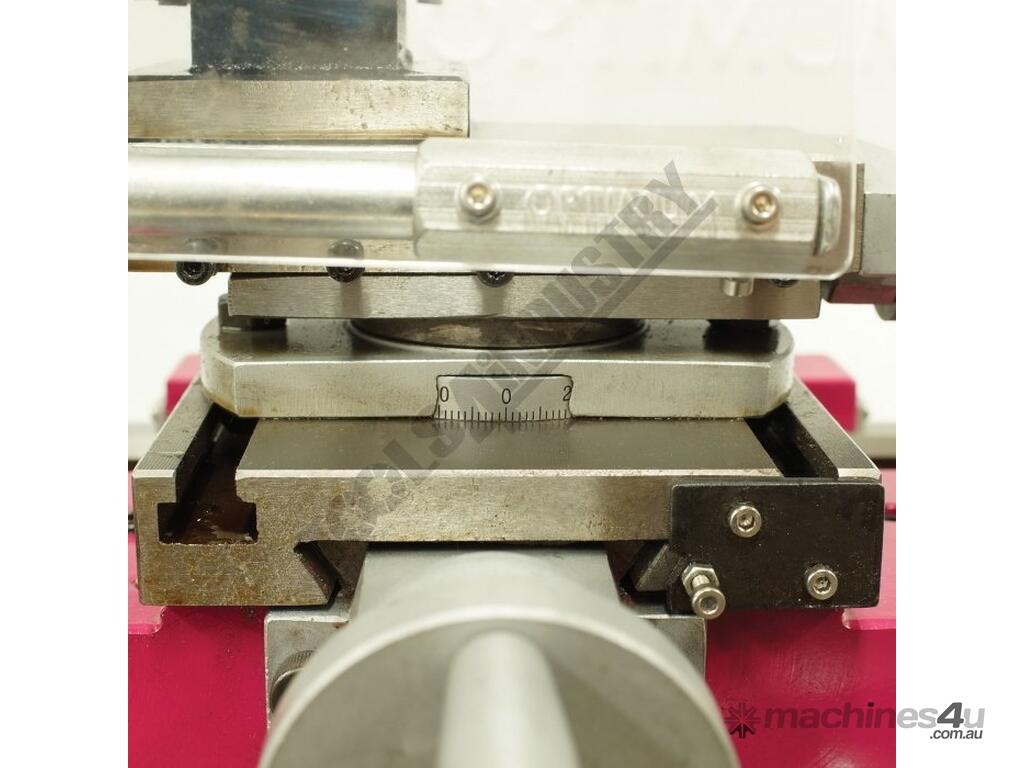

Cross Slide Travel (mm): 150

Compound Slide Travel (mm): 65

Leadscrew Type: Metric

Metric Cross Feed (X-Axis) (mm/rev): 0.01 ~0.10

Imperial Cross Feed (X-Axis) (inch/rev): ~

Metric Longitudinal Feed (Z-Axis) (mm/rev): 0.085 - 0.83

Imperial Longitudinal Feed (Z-Axis) (inch/rev): ~

Metric Thread Steps & Pitch (No. / mm): 18 (0.2 - 3.5)

Imperial Thread Steps & TPI (No. / TPI): 21 (8 - 56``)

3 Jaw Chuck Diameter (mm): 160

4 Jaw Chuck Diameter (mm): Optional

Spindle Steps / Speeds (No. / rpm): 12 (125 - 2400)

Motor Power (kW / hp): 1.5 / 2

Voltage / Amperage (V / amp): 240 / 10

Shipping Dimensions (L x W x H) (cm): 153 x 71 x 58

Nett Weight (kg): 280

Since 1990, Shaw Machinery has been a trusted name in Engineering, with our origins dating back to 1968. Our seasoned, expert team will help guide you through various options and provide the recommended machinery selection. If you can't find what you need, we'll search national and international sources to get what you need. Shaw Machinery's reputation for supplying a detailed range of top Metalworking Machinery brands has a long legacy in the industry and continues to be a significant reason that customers come to Shaw for solutions.

Go to the Shaw Machinery showroom to see the rest of our machinery, send Shaw a message about the item you are interested in, or give Shaw Machinery a call - we are happy to answer any of your questions and provide professional advice for your business.

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print